Infrastructure

SELECTION OF RAW MATERIAL

We acquire the finest quality of virgin PVC Resin from Japan and South Korea and have partnered with local farming community for uninterrupted supply of natural fibres.

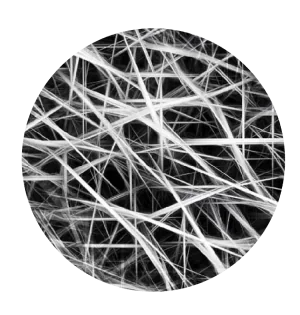

MATRIX FORMULATION

These polymers and fibres, when mixed with minerals, coupling agents, heat stabilisers and necessary additives under monitored temperature and pressure, form a homogeneous matrix which is responsible for bonding between the polymers and fibres.

INTERFACE STRENGTH

The bonds and density of the compound are the deciding factors in the interfacial strength of each board. This is achieved with a mathematical accuracy of fibre dispersion and interfacial bonding to achieve better impact resistance and internal strength of Indowud NFC.

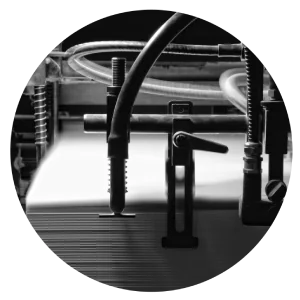

MANUFACTURING

The compound is then extruded under controlled temperature in a continuous process through various calibration pads. The cooling bracket is the final stage of the process flow. After which the boards are taken for further processing like transverse cutting, trimming, and surface processing.