Plywood Discussion: Pros and Cons of Plywood

Plywood has been one of the most conventional building materials. As the name its self suggests, plywood is made of plies or better known as veneers glued together under pressure for better strength, stability, and density.

To understand the pros and cons of plywood, it is suggested to understand its manufacturing process. Logs are examined and picked up based on hardwood/softwood species. The logs are then kept in large ponds for conditioning & to protect against splitting.

Next, the conditioned log is taken and cut to the desired length. The barks are also removed. Eventually, the logs are peeled into veneers using a rotatory lathe machine. The veneers that are produced are in the form of continuous sheets. These are clipped as per the desired width and length. The grade of veneer decides upon the quality of plywood and so veneers that are visibly not up to the mark are discarded. These veneers are typically high in moisture and require drying so that bonding between them becomes easy. For this, the veneers are dried to have a moisture content between 5 to 15%.

After drying, The veneers are composed by segregating as the face, core, or back veneer. These are then bonded with adhesive which is formaldehyde-based, Melamine or Phenol based. The number of veneer layers determines the thickness of the final Plywood. These panels are compressed in a controlled temperature and pressure and from the cold press are taken into the hot press. Finally, these are sanded to give a smooth surface and uniform thickness. Plywood is then trimmed to the final size at a later point.

Pros of Plywood

Plywood looks aesthetically good and if a good quality veneer is used, it looks even more attractive. Its strength and stability is due to cross grain structure. Various grades of Plywood like BWR, BMR and marine plywood have become a favourite choice for many builders and home owners. Besides this, wood fibreboard, MDF/ HDF are further more options. In the recent past, WPC manufacturers have also increased hoping to capture a share of the plywood market.

Cons of Plywood

The basic nature of every wood-based panel product is that termites can easily attack them in search of ligneous or Cellulose material. So, even the best quality plywood loses its ability to shield against termites once the chemicals evaporate. No Plywood is eco-friendly. Every plywood requires the felling of trees. The trims cannot be recycled and hence are not favorable to the environment. They are dumped in an unorganized manner. Plywood cannot be bent or thermoformed to form any shape and emit VOCs that are carcinogenic.

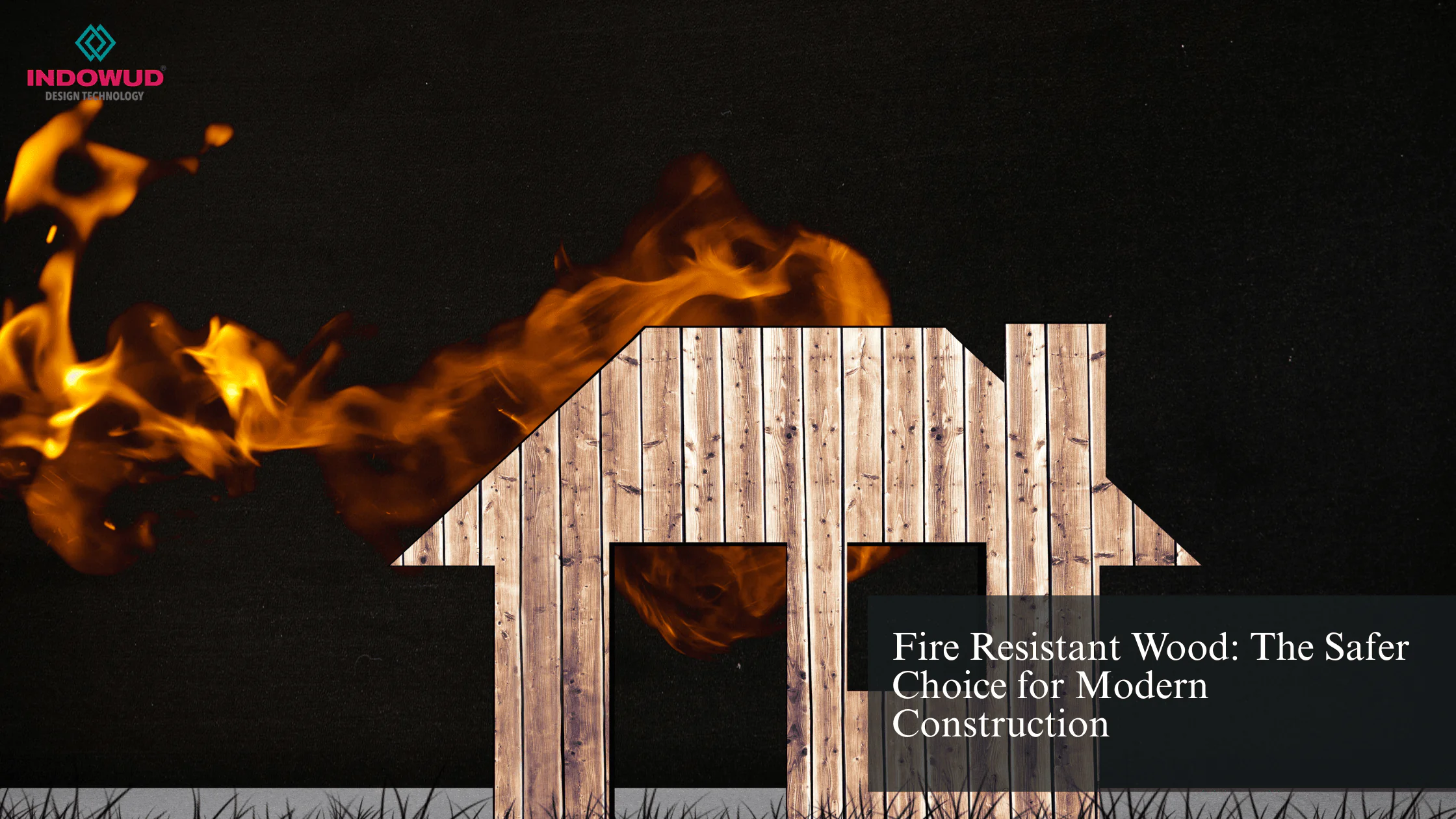

The nature of Plywood is also that it is not waterproof and doesn’t survive the cyclic changes in weather. Eventually, the veneers break due to swelling and shrinkage. Plywood is susceptible to algae, fungi, and bacteria. Even rodents chew plywood to sharpen their teeth. The smoke that plywood emits is more dangerous than the fire itself. Incase of the unlikely event of a fire, the pungency of smoke is extremely hazardous and leads to fatality. Fire retardant plywood or WPC boards (commonly called WPC plyboard) are not smoke suppressants either. Indowud NFC addresses all the cons of plywood and hence rightly called a superior alternate of wood, in many ways.

FAQs

1) Why are most Plywood marketed as termite proof?

Any Plywood is termite proof only until their chemicals are active. Anti – termite solution is added to shield them against termites. However once the chemicals fade away, any plywood is prone to termite invasion unlike Indowud NFC.

2) What are eco-friendly plywood?

Plywood is not eco-friendly. Any plywood requires the cutting of trees and support deforestation. Hence in simple terms, eco-friendly plywood doesn’t exist. Whereas Indowud NFC is eco-friendly, sustainable, and recyclable.

3) Is there a water proof plywood?

Waterproof plywood is a moisture-resistant board but not waterproof in the true sense. The nature of plywood is such that it absorbs water due to changes in atmospheric moisture. Indowud NFC is waterproof material and is suitable for exterior and interior applications.